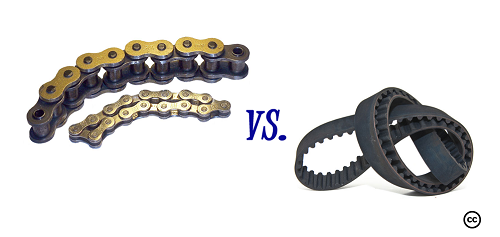

Difference Between Chain Drive and Belt Drive

Chain Drive vs. Belt Drive

Both a chain drive and a belt drive are part of mechanisms that allow locomotion and a transfer of power within a particular piece of machinery. The usual application of a chain drive and a belt drive is to transfer power or as a method to move objects, like hoisting or conveying. Chain drives and belt drives are often used in many vehicles (like bicycles, motorcycles, and automobiles) as well as other mechanical applications, including garage doors.

Both chain drives and belt drives are designed as continuous and endless loops that move when the engine is running or in use. The chain drive, as its name implies, is made up of chains with special structures like teeth on one side and a corresponding etch on the other side (drive shafts). The chain drive works when the two sides link together, which encourages the movement of the chain as well as power. The designs and structures also allow the chain to keep and hold it in one place and one direction.

On the other hand, the belt drive is a smooth and wide span of synthetic material. The belt drive itself can be made from rubber, plastic, and other synthetic substances.

Each kind of drive has its own set of advantages and disadvantages.

The chain drive is stronger and more durable because it is made of metal. It is also more dependable to use and easier to repair. Moreover, it is easier to change gears in the instance when the chain is broken. However, the chain drive’s downsides include requiring lubrication to run smoothly and seamlessly, and the fact that the chain can get stuck in the links or mangle itself while on the run. Simple chain drives usually contain two gears; the more complicated designs tend to have two or more gears in the design. The additional gears are called “idle gears” and usually don’t contribute to the drive and its overall ratio. The only thing that impacts the gear ratio is the number of teeth in the first and last gears.

Chain drives are usually seen in bikes, motorcycles, and automobiles. They are also used in many industries such as the military (for tanks) and in the mining industry. The classification for a chain drive is as follows: roller chain, double pitch roller chain, silent (inverted tooth) chain, detachable link chain, and engineering steel chain. There are also three types of load classification for chain drives: smooth load, moderate shock load, and heavy shock load.

On the other hand, a belt drive is best used for machines and is very useful in inspection for damage or wear. The surface of the belt can more easily show evidence of the mentioned imperfections and can be an indication that purchasing a replacement may be neccesarry. Another advantage of the belt drive is that it requires fewer adjustments and is quieter, cleaner, and runs more smoothly compared to the chain drive. This type of drive doesn’t require lubrication, which can be considered as an added cost to a machine’s maintenance. The bad thing about belt drives is the fact that they often expire earlier compared to the chain drive. Belt drives can also slip or snap if the belt isn’t maintained or at least inspected for signs of damage and wear.

The types of belt drives are diverse. The list of their kinds include flat belts, round belts, vee belts, multi-groove belts, ribbed belt, film belts, metal belts, endless round belts, timing belts, specialty belts, rolling roads, and flying rope.

Summary:

1.Both chain drives and belt drives are methods to transfer power and objects within a machine. The main difference between the two drives is that a chain drive is powered by a chain loop, while a belt drive is powered by a belt.

2.Another notable difference is the material of the drive. Chain drives are made of metal, which makes them more durable and stronger compared to a belt. The metal chain is designed to have a design that corresponds to the other side. On the other hand, the belt drive is made of synthetic materials, and it is also flatter and smoother.

- Differences Between Fraternity And Sorority - January 8, 2014

- Differences Between Lucite and Plastic - January 7, 2014

- Differences Between Oil and Butter - January 6, 2014

Search DifferenceBetween.net :

7 Comments

Leave a Response

References :

[0]https://commons.wikimedia.org/wiki/File:Roller_chains_Toothed_belts.png

Hello sir ,

I want to run 3 flat horizontal cutters , which is evenly placed , I have used chain drive for this operation , due to gravitational force , the chain is getting slip !

I know that u won’t understand from this

Iam struggling with this problem , and this my academic project , plz help me out

pH:-7411814770

Bangalore

can i know about efficiencies of chain drive and belt drive?

You lose about 30 percent of power transfer with a belt. Compared to 3 percent with a chain. Its enough to be noticed on motorcycles. Which is why I change all of my Harleys to a chain drive.

Hi, I would like to know, can a chain run at high speed in a lenth of 4 meters in total with only 2x pullys one left an one right, the speed makes my v-belt flapper on the middle where I can not put in a tentioner because of no space.

So the question is what can take more speed, a belt or a chain?

Chain drive can handle more high speeds but are more pricey and harder to get on 🙂

Which among belt and chain drive is more efficient, and which one is more suitable for conveying??

At which maximum speed we can use chain. Drive ?