Difference Between Through Hardening and Case Hardening

Heating by means of electromagnetic induction has been a popular practice for decades. Well, there are many methods to heat metallic materials and each method has its own advantages and downsides. Induction heating is more energy efficient and inherently more environment friendly than other heat sources. It provides much better surface quality of heated metallic materials. One of the most common applications of induction heat treatment is the hardening of steels. A common hardening process for steels involves heating it to the austenitizing temperature range and rapidly quenching it below the critical temperature. In general there are two common ways to harden steel to the desired level: through hardening and case hardening.

What is through hardening?

Through hardening is a process of heat treatment of medium and high carbon steels in order to increase the hardness and tensile strength of metallic alloys. First, the steel is heated to the austenitizing temperature range and is kept at a temperature for a long period of time, and finally quenched below the critical temperature when martensite starts to form. Martensite is a very hard form of steel with a crystal structure. Hardening may be done to obtain a certain combination of hardness, wear resistance, and contact fatigue strength without affecting the core structure of the material. The heat treatment process hardens the material all the way through from the surface to the core. The process is also known as quenching and tempering.

What is case hardening?

Case hardening is a processing method used to harden the surface of a metal object by reinforcing an additional layer of a yet another metal alloy. It is common practices to heat treat metallic materials to harden them which make them more wear resistant. But metals are often low carbon grade, meaning they do not have enough carbon content to heat treat and harden properly. Case hardening can be done by a couple of methods. First one is the thermochemical diffusion method, which alters the chemical composition of the surface with carbon, boron, and nitrogen. So, the process involves adding an extra layer of carbon or nitrogen into the surface layer to achieve the desired hardness and strength. Another method is applied energy, rather than altering the chemical composition of the surface. This results in a hard quenched surface without additional alloying species.

Difference between Through Hardening and Case Hardening

Process

– Hardening is done to obtain certain properties or combination of properties such as strength and wear resistance. Through hardening, also called neutral hardening, is a process used to harden an entire cross section of the steel metal alloy via rapid quenching. The heat treatment process hardens the material all the way through from the surface to the core. Case hardening, on the other hand, is the process of hardening only certain selected areas of the steel metal alloy, the outer surface layer to be precise, while keeping the inside layer soft.

Hardening Method

– Through hardening can be achieved in three steps. First, the steel is heated to the austenitizing temperature range and is kept at a temperature for a long period of time, and finally quenched below the critical temperature to eliminate excess brittleness from the treated alloy. There are a couple of approaches to case hardening. First, there is the thermochemical diffusion method, which alters the chemical composition of the surface, and then there’s applied energy which alters the surface metallurgy. In either case, a thin layer of a harder metal alloy forms at the surface.

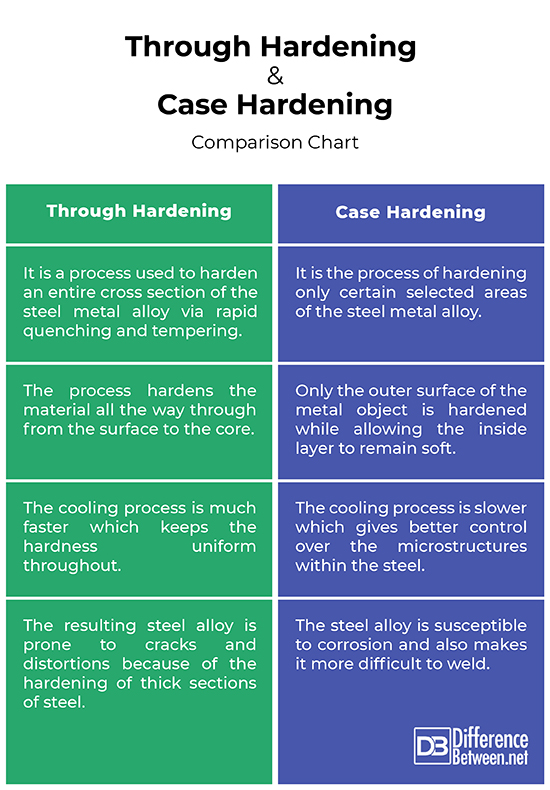

Through Hardening vs. Case Hardening: Comparison Chart

Summary

In a nutshell, case hardening is simply a process of taking a low-carbon metal and heat treating it in such a way that the surface becomes hard but the inside stays soft. Case hardening allows for a greater control over the microstructures of the metal alloy. In doing this, you can combine the best characteristics of a soft and hard metal into one part. Through hardening, on the other hand, is a process of hardening the entire section of the metal as opposed to case hardening. Besides, both the methods produce high-quality steel components to meet specific design or performance requirements. At the end of the day, it depends on your needs or preferences.

What does through hardening mean?

Through hardening is a process of hardening the entire section of the metal allow, as opposed to case hardening which creates a harder outer layer while keeping the inside soft.

What are the 2 methods of case hardening?

Carburizing and nitriding are two methods of case hardening. Carburizing is the addition of carbon to the surface of low-carbon steels. Nitriding is a similar process in which nitrogen is diffused into the surface to harden it.

What are the different types of hardening process?

There are many heat treatment processes used to alter the surface structure of metal alloys, including grind hardening, flame hardening, induction hardening, high frequency resistance hardening, diffusion, methods, and more.

What is case hardening?

Case hardening is the process of hardening the certain selected areas of the metal to increase the hardness and wear resistance while allowing the rest of the part to remain unaffected by the process.

What are the 3 hardening process?

Three types of steel hardening processes include case hardening, through hardening, and flame hardening.

Why do we do case hardening?

Case hardening is done when the heating can be localized to areas where the metallurgical changes are needed.

- Difference Between Caucus and Primary - June 18, 2024

- Difference Between PPO and POS - May 30, 2024

- Difference Between RFID and NFC - May 28, 2024

Search DifferenceBetween.net :

Leave a Response

References :

[0]Davis, Joseph R. Surface Hardening of Steels: Understanding the Basics. Ohio, United States: ASM International, 2002. Print

[1]Rudnev, Valery, et al. Handbook of Induction Heating. Florida, United States: CRC Press, 2017. Print

[2]Salonitis, Konstantinos. Grind Hardening Process. Berlin, Germany: Springer, 2015. Print