Difference Between Dielectric Grease and White Lithium Grease

There are so many types of multi-purpose grease available for vehicle maintenance purposes. Yes, we’re talking about real grease, the kind that makes your car go that extra mile, the grease that’s widely used in all automotive applications. Grease is a vital lubricant that possesses a high dropping point, good shear stability and impressive anti-wear characteristics which are necessarily required for automotive applications like automotive wheel bearing, chassis, etc. Grease is typically made of base oil, plus a thickening agent, and specific additives to meet the requirements of the applications. We have the two major types of grease broken down for you to help you better with your next DIY project. Proper selection and use of different types of grease in automobiles is very important for their proper functioning and on the long run. Let’s take a look at the two common types of automotive grease – dielectric grease and white lithium grease.

What is Dielectric Grease?

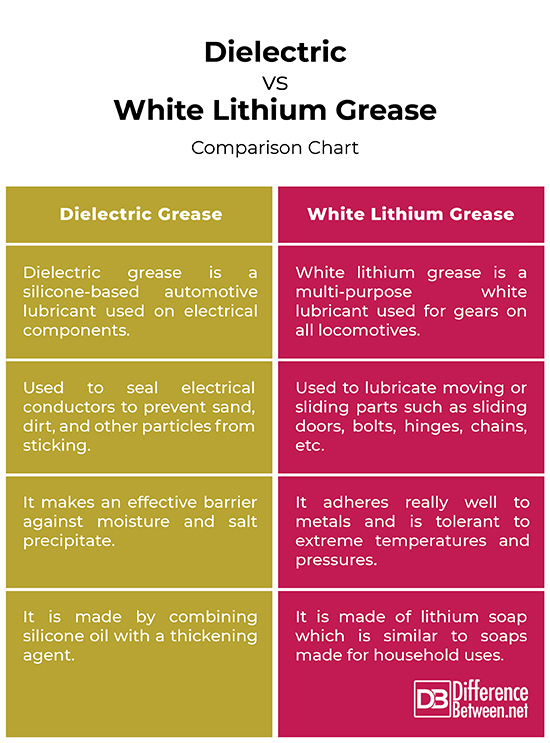

Dielectric grease is a silicone-based automotive lubricant used under electronic ignition modules to transfer heat from the electronics. It is a waterproof grease that repels moisture out of a connection. Because it is non-conductive, it does not allow the flow of electrical current. Preventing moisture improves the ability of the connector to conduct electricity. It combines silicone oil with a thickener to reduce connection issues in automobiles and to seal electrical conductors to prevent sand, dirt, and other particles from sticking to the surface. It seals perfectly against moisture invasion, preventing corrosion at connections. Silicone grease can be used on all your electrical connections and on battery terminals. They are widely used on spark plug cable rubber boots as well as a sealant for spark plug threads. They also help prevent electrical failures caused by moisture and corrosion.

What is White Lithium Grease?

White lithium grease is a multi-purpose white lubricant used for gears on all locomotives, including those with motor worm gears. They come in aerosol cans and in small squeeze tubes. They are commonly used for metal-to-metal applications that require some heavy-duty lubrication such as car door hinges, springs, door rails, etc. It’s an all-weather lubricant used for auto, farm, marine, and household applications. They are typically made of lithium soap which is the alt from fatty acids and they adhere really well to metal, and are tolerant to extreme temperatures. This is why they are commonly used for moving or sliding parts such as sliding doors, bolts, hinges, chains, etc. The lithium-based grease is often used in chassis lubrication for improved protection, particularly for gears, sprockets, and more.

Difference between Dielectric Grease and White Lithium Grease

Basics of Dielectric Grease and White Lithium Grease

– Dielectric grease, often called silicone grease, as the name suggests, is a silicone-based lubricating agent which is a combination of silicone oil and a thickening agent. It is sometimes called tune-up grease and it seals perfectly against moisture invasion, preventing corrosion at connections. The word dielectric simply means non-conducting which is nearly synonymous with the word insulator, meaning it does not allow the flow of electrical current.

White lithium grease is a multi-purpose grease used for gears on all locomotives, including those with motor worm gears. Lithium grease usually comes in aerosol cans and in squeeze tubes.

Composition in Dielectric Grease vs. White Lithium Grease

– Dielectric grease is a silicone-based dielectric compound made by combining silicone oil with a thickening agent and used as a vital lubricant for sealing, protecting, and insulating electrical components of automobiles. The silicone oil is mostly a silicone-based organic polymer called polydimethylsiloxane and the thickening agent is amorphous fumed silica.

While lithium grease, on the other hand, is a white lubricant typically made of lithium soap which is similar to soaps made for household uses except they are soluble in oil instead of water. They mainly contain hydrocarbon oils along with other components.

Properties in Dielectric Grease vs. White Lithium Grease

– The lubricating oil within the lithium-based grease is held tightly against a metal surface which helps it do a better job than oil in lubricating and protecting against rust. They adhere really well to metal and are tolerant to extreme temperatures, providing additional protection and longer bearing life.

Dielectric grease, on the other hand, is a waterproof grease that repels moisture out of a connection. Because it is non-conductive, it does not allow the flow of electrical current. It is silicone based, which makes it an effective barrier against moisture and salt precipitate.

Use of Dielectric Grease vs. White Lithium Grease

– Dielectric grease is kind of a tune-up grease commonly smeared inside spark plug boots so the boots can be pulled off after long hours of running. They are commonly used under electronic ignition modules to transfer heat from the electronics, and to reduce connection issues in automobiles and to seal electrical conductors to prevent sand, dirt, and other particles from sticking to the surface.

Lithium soap, on the other hand, is a common thickening agent in automotive lithium-based grease to enhance its ability to withstand extreme temperatures and commonly used for moving or sliding parts such as sliding doors, bolts, hinges, chains, etc.

Dielectric vs. White Lithium Grease: Comparison Chart

Summary of Difference Between Dielectric Grease and White Lithium Grease

In a nutshell, both are lubricants that serve different purposes. The properties of a grease are determined by the quality of the oil it is made of. Dielectric grease is made by combining silicone oil with a thickening agent which makes an effective barrier against moisture and salt precipitate. White lithium grease, on the other hand, is a multi-purpose grease made of lithium soap, similar to the soaps used in household applications except it is oil-soluble rather than water-soluble. Besides, they both reduce friction and wear and dissipate heat.

- Difference Between Caucus and Primary - June 18, 2024

- Difference Between PPO and POS - May 30, 2024

- Difference Between RFID and NFC - May 28, 2024

Search DifferenceBetween.net :

1 Comment

Leave a Response

References :

[0]Image credit: https://www.flickr.com/photos/internetarchivebookimages/16676212412/

[1]Image credit: https://media.defense.gov/2013/Mar/01/2000071769/-1/-1/0/130228-F-AK347-080.JPG

[2]Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair. Boston, Massachusetts: Cengage, 2015. Print

[3]VanGelder, Kirk. Fundamentals of Automotive Technology. Burlington, Massachusetts: Jones & Bartlett Learning, 2017. Print

I sprayed lithium grease into an automotive multiwire electrical connector with hopes of inhibiting corrosion. Will this cause potential shorting problems between the different circuits? Do I have to spray it all out with electronic cleaner and apply dielectric grease, or am I still Safe?

Thanks