Difference Between NPT and NPTF

Piping finds tons of uses and applications in the engineering discipline from conduits of liquids and gases to structural members. There are many materials that are universally used to make pipe fittings including PVC, ABS, nylon, PP, steel, copper, aluminum, brass, cast iron, and many more. Most machines use a combination of two or more types of fittings throughout their hydraulic system. So, it is important to understand the basics of how these fittings work and how to differentiate between different types of fittings. Two of the common sealing thread types include the NPT and the NPTF.

National Pipe Taper (NPT)

NPT, or National Pipe Taper, is a common US standard for tapered threads used for joining pipes and fittings for over a hundred years. It is an American standard thread which is often more specifically referred to as FPT for female threads (internal) and MPT for male threads (external). It was originally designed by William Sellers, an American mechanic engineer and businessman. It was used by clockmakers back then, but later these threads became the American national standard in 1864. Today, it’s the most widely used type of thread in the United States for consistent threading practice. It’s available in iron and brass for low pressure applications and carbon and stainless steel for higher pressure applications. NPT specifications are collected at ANSI B1.20.1 regulation.

National Pipe Taper Fuel (NPTF)

NPTF, or National Pipe Taper Fuel, is a dryseal tapered pipe thread, which is kind of a modified NPT thread but provides better seals than NPT threads. The ‘f’ in NPTF refers to fuel and as the name suggests, it is derived from NPT and even shares the same diameter, taper shape, and threads per inch with NPT. But that’s where the similarities end. The NPTF is defined by the ASME B1.20.3 regulation, which is more effective in providing a better seal in comparison to NPT threads. It is called the Dryseal American National Standard Taper Pipe Thread. Although based on the NPT thread, the NPTF is slightly modified for greater accuracy, making a pressure-tight joint without a sealer. The NPTF threads are less likely to leak because the seal is created between the crest and the root of the mating threads.

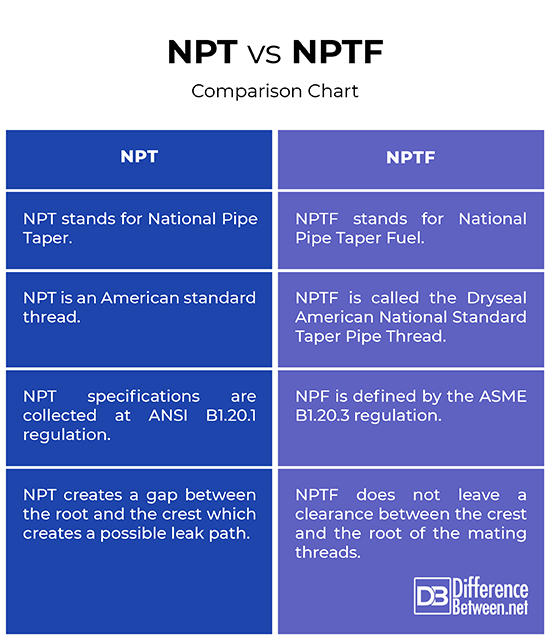

Difference between NPT and NPTF

Standard

– While NPT and NPTF are two of the most commonly used types of taper pipe threads used all over the world, there are subtle differences between the two threads. NPT, or National Pipe Taper, is an American standard thread which is often more specifically referred to as FPT for female threads (internal) and MPT for male threads (external). The NPTF (or National Pipe Taper Fuel), on the other hand, is called the Dryseal American National Standard Taper Pipe Thread, and is the modified variant of the NPT but facilitates better sealing.

Sealing Performance

– NPT threads do no seal well without the help of thread sealants, because the design creates a slight clearance between the crests and the mating roots. Also, the sealing performance decreases rapidly with re-assembly and larger sizes are more prone to leaking. NPTF, on the other hand, are modified NPTs designed to create a better seal since it is created between the thread crests and the mating roots, providing a better seal in comparison to NPT threads. This also helps make a pressure-tight joint without a sealer.

NPT vs. NPTF: Comparison Chart

Summary

While NPTs do not make good sealers but despite their downsides, there are some great advantages of using NPTs as well. For one, NPT fittings are readily available and they come in a great variety of sizes, shapes, combinations, and materials. They are the most commonly and widely used thread types to offer a simpler assembly without the need of seals or slaves. NPTF threads are designed to provide a dry mechanical seal, however, lubricant is often still used for assembly. Unlike NPT threads, NPTFs do not require a seal to make a pressure-tight joint. NPTF is based on the NPT thread, but with some modifications and greater accuracy.

What is NPTF stand for?

NPTF stands for National Pipe Taper Fuel, which is a modified NPT thread capable of making a pressure tight joint without a sealer, thus providing a better seal that NPT threads.

What does NPTF mean in plumbing?

The NPTF, defined by ASME B1.20.3, is widely used in fluid power systems. This thread is ideally designed to provide a dry mechanical seal for a wide array of applications including fuel connections, high pressure pipes, electrical conduits, and more.

Can NPT and NPS be used together?

It is true that both NPT (National Pipe Tapered) and NPS (National Pipe Straight) have the same 60-degree thread angle, shape, and same flat peaks and valleys. Despite that, NPT threads are tapered whereas NPS threads are straight. So, they are not compatible with each other. While they can engage, they will not seal properly.

Are NPT and NPTF interchangeable?

NPT creates a gap between the root and the crest which in turn creates a possible leak path. So, you need a sealant compound to gain a proper seal. Unlike NPT threads, NPTF achieves a proper seal without any sealer. The L1 gauge requirements for both the thread types differ for threads over ½ inch in size. So, NPT and NPTF are not interchangeable.

Can I use NPT with NPTF?

Mixing both the threads would require thread sealants for pressure-tight, leakproof connections. With proper inspection, NPT threads can be reused. But that’s not the case with NPTF threads. While both can engage, they do not seal properly.

- Difference Between Caucus and Primary - June 18, 2024

- Difference Between PPO and POS - May 30, 2024

- Difference Between RFID and NFC - May 28, 2024

Search DifferenceBetween.net :

Leave a Response

References :

[0]Ogot, Madara and Gul Kremer. Engineering Design: A Practical Guide. Indiana, United States: Trafford Publishing, 2004. Print

[1]Duffy, Own C., et al. Fundamentals of Mobile Heavy Equipment. Massachusetts, United States: Jones & Bartlett Learning, 2017. Print

[2]Madsen, David A. and David P. Madsen. Engineering Drawing and Design. Massachusetts, United States: Cengage Learning, 2016. Print