Difference Between Stocktaking and Stock Control

One of the most significant assets in a company is inventory. It ranges from raw materials, unfinished goods, and finished goods. The form notwithstanding, maintaining stocks or inventory is costly and thus should be handled efficiently. Stocktaking and stock control are two terms that you cannot escape when you think of stock management. But did you know they are not the same? Though very similar, they have their differences. Let’s explore them in this article.

Stocktaking

Stocktaking refers to the counting of on-hand inventory. It is the physical verification of the quantities and conditions of items in a store. It is crucial as it affects purchasing, production, and sales.

Stock refers to anything from raw materials such as automobile parts, clothing, concrete, and household items, to finished products available for sale to consumers.

Types of Stocktaking

The best method of stock-taking is using software that provides daily and real-time information. Though more expensive its benefits outweigh the other methods.

- Periodic Stocktaking- It happens at the end of an accounting period or on a set periodic basis.

- Spot-checks- These are scheduled or sometimes random checks that are done on tills. They can help ascertain whether what the software is giving is right or if there are discrepancies. Spot checks are also good if you think theft is occurring.

- Continuous Perpetual Stocktaking- This is done throughout the year at different points.

- Stock-out Validation- It happens when stocks have gone dangerously low.

- Annual Stocktaking- Done in the last month of the financial year and sometimes may require a premise to close for a few days.

Benefits of Stocktaking

- Stocktaking allows one to accurately track the physical stock, what has been sold and what has not in a report. This helps in assessing performance and profitability while ensuring efficiency in the business.

- Helps prevent stock-outs that cause services or products to go out of the market.

- It increases profits by reducing losses and wastages

- Helps the management accurately know which products are doing well and which are not.

- Ensures assets are right on the company’s balance sheet

- Identifies shrinkage, damage, and theft by monitoring real-time stock levels

- Monitors seasonal stock and fast expiry products promptly

- Helps keep the pricing and pricing strategies up to date with the current purchase price.

- Helps maintain gross profit levels or find out why you are not hitting your goals.

Stock Control

Stock control refers to the process of maintaining the appropriate stock quantity for a business to meet its customer demands. This is done while ensuring the costs of holding stock are kept at a minimum.

The purpose of stock control is to make sure the business always has enough stock to sustain its customers while balancing the amount spent on acquiring and storing stock.

Methods of Stock Control

Just in Time (JIT)

In this method, the stock is ordered as and when it is required to keep costs low and liquidity high. The company must be well organized to purchase at the right time though and the suppliers reliable to fulfill the requirements to avoid stock-outs. The risk of stock-outs also exists in the case of large orders.

First In First Out (FIFO)

The system is common among people dealing with perishable goods. It ensures that stock does not expire before use. It allows the stock that came in first to be dispensed before the ones that came at a later date.

EOQ (Economic Order Quantity)

EOQ is a mathematical formula that is complex in nature, and endeavors to maintain stock at an optimal level. The calculations within this formula are time-consuming and it’s easier to consult a professional for guidance or adapt software that has inbuilt EOQ calculators to help you out.

Other methods include batch control, vendor-managed inventory, and stock reviews.

Benefits of Stock Control

- Eliminates stock-outs hence meets the customers’ needs adequately

- Reduces the chances of overstocking

- Removes the need for guesswork as accurate data is available

- It protects against theft or missing stock.

- Boosts customer satisfaction.

- Helps save time and money.

Similarities between Stocktaking and Stock Control

- Both stocktaking and stock control ensures efficient management of stock in a company.

Differences between Stocktaking and Stock Control

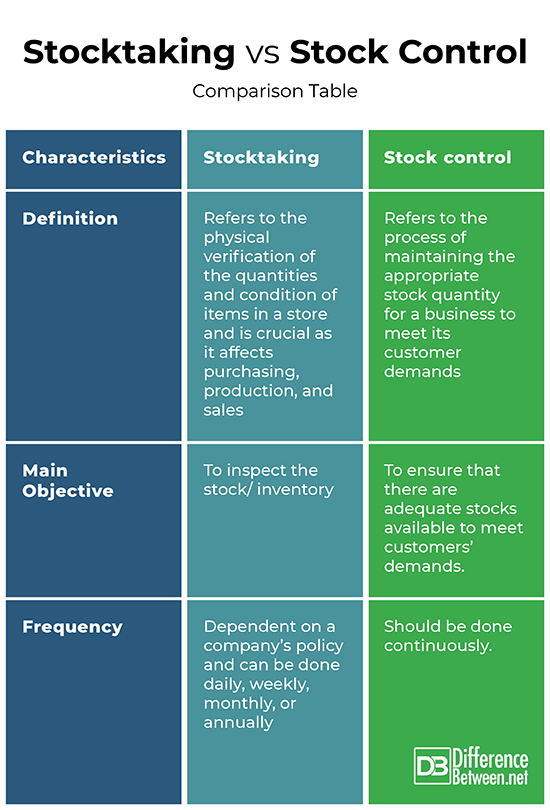

Definition

Stocktaking is the physical verification of the quantities and condition of items in a store and is crucial as it affects purchasing, production, and sales.

Stock control refers to the process of maintaining the appropriate stock quantity for a business to meet its customer demands.

Main Objective

The main objective of stock-taking is to inspect the stock/ inventory while the main objective of stock control is to ensure that there are adequate stocks available to meet customers’ demands.

Frequency

The frequency of stock-taking is dependent on a company’s policy and can be done daily, weekly, monthly, or annually while stock control should be done continuously.

Stocktaking vs. Stock control: Comparison Table

Stocktaking vs. Stock Control: Conclusion

Stocktaking refers to the physical verification of the quantities and the condition of items in a store. Stock control refers to the process of maintaining the appropriate stock quantity for a business to meet its customer demands. Though both check different aspects, they are very similar in that they ensure sufficient inventory and efficiency in sales and production.

FAQS

What is the difference between stocktaking and inventory?

Stocktaking is the physical verification of the quantities and the condition of items in a store. Inventory refers to anything from raw materials to finished products that are available for sale to consumers.

What is the difference between inventory control and stock control?

Stock control refers to the process of maintaining appropriate stock quantities of finished products while inventory control refers to the process of maintaining quantities of either finished or components used to create a finished product.

What is the difference between stock taking and spot-checking?

Stocktaking is the physical verification of the quantities and the condition of items in a store. Spot checking refers to scheduled or sometimes random checks that are done on tills to ascertain the efficiency of the software.

Is inventory management and stock management the same

No.

- Difference Between Profit Center and Investment Center - July 2, 2022

- Difference Between Anti-Trust and Anti-Competition - June 6, 2022

- Difference Between Stocktaking and Stock Control - June 6, 2022

Search DifferenceBetween.net :

Leave a Response

References :

[0]Tony Wild. Improving Inventory Record Accuracy. Routledge, 2012. https://books.google.co.ke/books?id=lkYVAgAAQBAJ&printsec=frontcover&dq=Difference+between+Stocktaking+and+Stock+Control&hl=en&sa=X&ved=2ahUKEwjPg8LKmun3AhWQ_7sIHWegCGUQ6AF6BAgJEAI#v=onepage&q=Difference%20between%20Stocktaking%20and%20Stock%20Control&f=false

[1]Peter Schimitzek. The Efficient Enterprise: Increased Corporate Success with Industry-Specific Information Technology and Knowledge Management. CRC Press, 2003. https://books.google.co.ke/books?id=WE8q26SDcQYC&pg=PA218&dq=Difference+between+Stocktaking+and+Stock+Control&hl=en&sa=X&ved=2ahUKEwjPg8LKmun3AhWQ_7sIHWegCGUQ6AF6BAgDEAI#v=onepage&q=Difference%20between%20Stocktaking%20and%20Stock%20Control&f=false

[2]Fergus C & Hart J. Management Accounting: Principles & Applications. Pearson Higher Education AU, 2012. https://books.google.co.ke/books?id=hRTiBAAAQBAJ&pg=PA136&dq=Difference+between+Stocktaking+and+Stock+Control&hl=en&sa=X&ved=2ahUKEwjPg8LKmun3AhWQ_7sIHWegCGUQ6AF6BAgHEAI#v=onepage&q=Difference%20between%20Stocktaking%20and%20Stock%20Control&f=false