Difference Between Takt Time and Cycle Time

When developing and implementing project plans, project managers often think about strategies and methods for how they can reduce wasted time and resources to establish a smooth workflow based on customer demands. If you wish to achieve tangible results from your projects, a simple approach can take the guesswork out of changing a process; it’s called “Takt Time.” This is often confused with yet another similar term called “Cycle Time.” We break down the differences between the two metrics.

What is Takt Time?

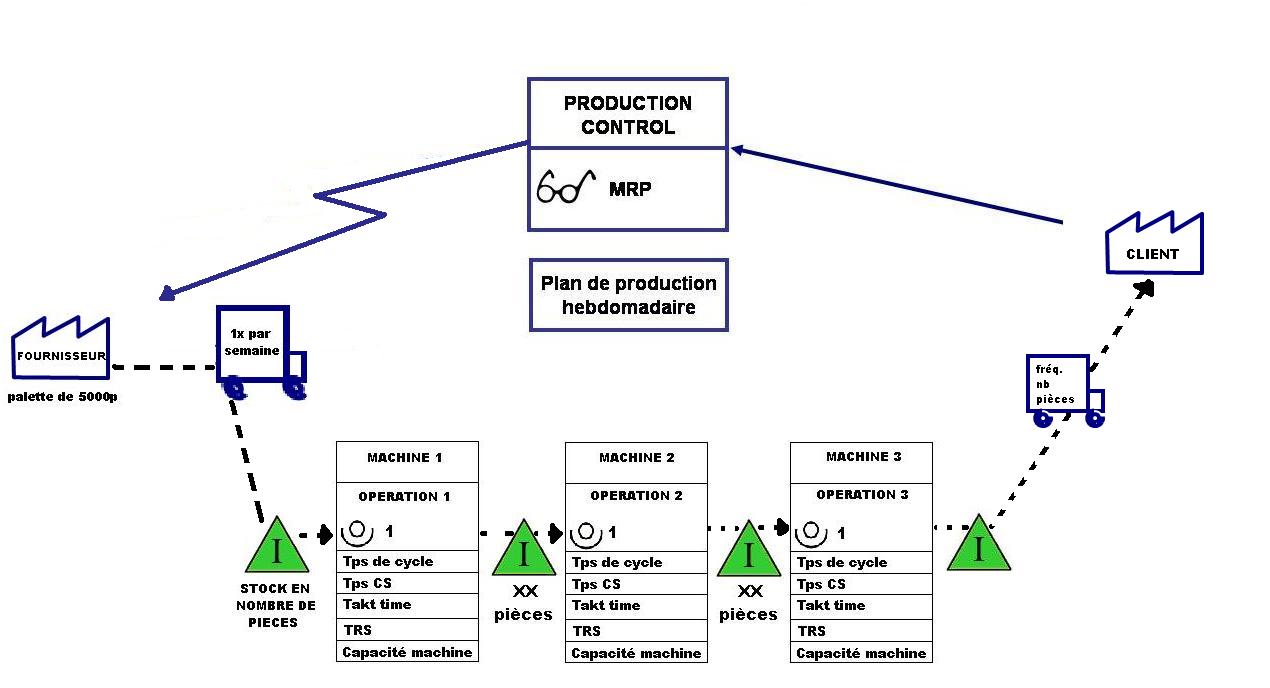

In this competitive world, companies strive to stand out from their competition, constantly seeking ways to minimize the amount of time and resources they use to ensure a smooth, timely workflow. Implementing takt time can help businesses of any size gain insights from the time they spend on their projects, fulfilling customer demands. But, what exactly is takt time? In describing business workflow, takt time is the rate at which customers require finished products. It is a strategic approach that synchronizes the rate of production to the rate of sales to customers. It is the maximum amount of time in which a product or service needs to be completed if the customer demand is to be fulfilled in time.

What is Cycle Time?

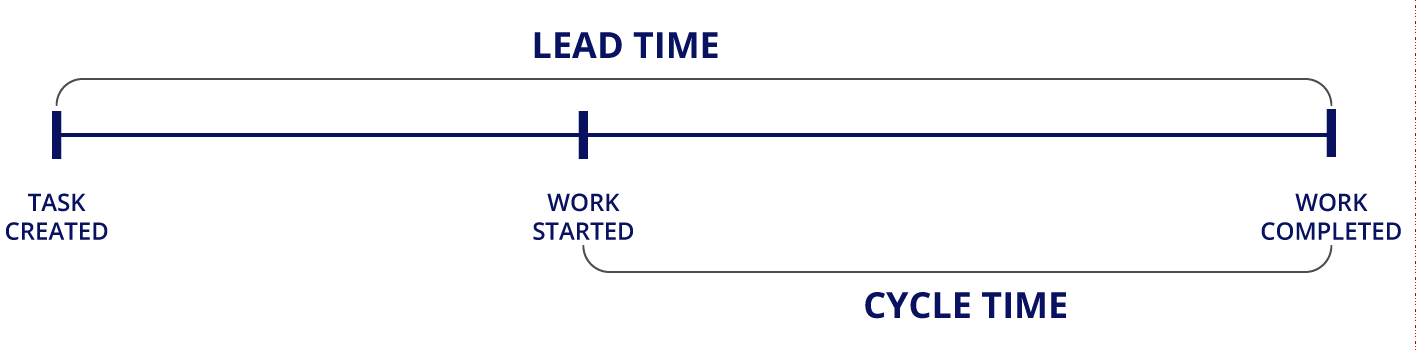

Cycle time is the actual amount of time spent on producing a product or providing a service, starting from the product being produced to the finished product getting ready for shipment. The basic premise of cycle time is shortening the overall business cycle, starting from identifying customer’s need to the receipt of payment for the product shipped or service delivered. Also called throughput time, it is the average time a process takes from start to completion. The actual assembly time of any product is referred to as its cycle time. The cycle time does not necessarily take the customer demands into consideration.

Difference between Takt Time and Cycle Time

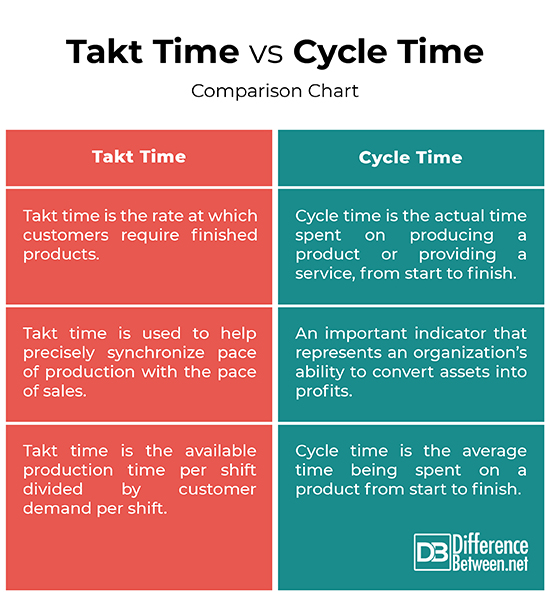

Meaning

– Takt time is directly linked to the customer orders or demands and can only be defined if any customer order exists. So, takt time is the rate at which customers require finished products. It is a strategic approach that synchronizes the rate of production to the rate of sales to customers. Takt in German can be translated as “keep in time.” Cycle time, on the other hand, is the actual assembly time of a product. It is the actual time spent on producing a product or providing a service, beginning from start to finish.

Calculation

– Takt time is the calculated value that describes the theoretical demand rate of a customer. Simply put, it is the rate at which a product must be produced in order to meet customer’s demand. For example, a customer demands 100 pens to be produced in an 8-hour shift.

Total time = 8 hours = 480 minutes

Break time = 50 minutes

Time available = 480 – 50 = 430 minutes

Takt time = the available production time per shift / customer demand per shift = 430/100 = 4.3 minutes = 258 seconds

Cycle time is the average time being spent on a product from start to finish. So, the best way to calculate the cycle time is to count the number of days it takes to complete a finished product. For example, if a production facility produces 100 units of product per 50 hour week. The average throughput rate is 1 unit per 0.5 hours, which is one unit per 24 minutes.

Cycle time = 24 minutes on average

Significance

– Although, both are synonymous, they are very different. Takt time is calculated in order to understand customer demand. Takt time is used to help precisely synchronize pace of production with the pace of sales. It is frequently used within lean production lines to ensure greater efficiency within the flow and reduced wasted time and resources. Cycle time is an important metric of time that tells how often a part is completed by a particular process. This is an important indicator that represents an organization’s ability to convert assets into profits.

Takt Time vs. Cycle Time: Comparison Chart

Summary

In a nutshell, takt time and cycle time are surely related, but they are not the same. Takt time is basically the time between completion of each finished product, if the customer demand is to be met. This is the rate of customer demand and is measured in ‘seconds per minute.’ Takt time is important to understand customer demand and request, and ensures greater efficiency within the flow and reduced wasted time and resources. Cycle time, on the other hand, is the average time being spent on a product, from start to completion. It tells how often a part is completed by a particular process. Specifically, talk time is the time between each finished product, if the deadline of the customers is to be met.

How do you calculate takt time and cycle time?

Takt time is calculated by dividing the available production time per shift by customer demand per shift. Cycle time is the average time being spent on a product from start to finish.

Is takt time greater than cycle time?

Ideally, takt time should match with cycle time. It shouldn’t be greater than cycle time and it shouldn’t be lower as well. If takt time is more than cycle time, the process could be overstaffed and there may be a slight risk of products being overproduced.

What is takt time example?

For example, if a customer demands 240 pens to be produced per day and the factory operates 480 minutes per day, then takt time will be 2 minutes (120 seconds).

Is lower takt time better?

Takt time is basically calculated to match the supply and demand within a company. So, if the demand is less, then takt time may be low, and vice-versa.

- Difference Between Caucus and Primary - June 18, 2024

- Difference Between PPO and POS - May 30, 2024

- Difference Between RFID and NFC - May 28, 2024

Search DifferenceBetween.net :

Leave a Response

References :

[0]Rother, Mike and Rick Harris. Creating Continuous Flow: An Action Guide for Managers, Engineers & Production Associates. Massachusetts, United States: Lean Enterprise Institute, 2001. Print

[1]Suri, Rajan. Quick Response Manufacturing: A Companywide Approach to Reducing Lead Times. Florida, United States: CRC Press, 2020. Print

[2]Meyer, Christopher. Fast Cycle Time: How to Align Purpose, Strategy, and Structure for Speed. New York, United States: Simon and Schuster, 2010. Print

[3]Image credit: https://commons.wikimedia.org/wiki/File:LEAND-AND-CYCLE-TIME.png

[4]Image credit: https://commons.wikimedia.org/wiki/File:VSM5.JPG