Difference Between Granulated Sugar and Castor Sugar

What is Granulated Sugar?

Granulated sugar is solid sugar that has been grown into relatively large distinct crystals. It usually has a paper-white color and is used extensively in baking. Granulated sugar is made from sucrose. Sucrose is a sugar that is predominantly derived from sugarcane and is composed of a mixture of fructose and glucose. Granulated sugar is usually resistant to becoming fused, so it normally will not cake or clump at high temperatures. This property of not caking easily makes transportation of granulated sugar easier.

Larger sugar grains will be harder to dissolve than smaller sugar grains. Granulated sugar is used because sugar broken up into crystalline grains is an effective way to deal with large quantities of sugar in bulk. Granulated sugar tends to be more often used in making pastries where the sugar is incorporated into the bulk of the pastry as opposed to being used as a topping.

Sugar is a type of carbohydrate. Two important sugar types, though not the only types, are monosaccharides and disaccharides. Monosaccharides consist of a single unit or molecule of sugar. These include glucose, also called blood sugar, and fructose, also called fruit sugar. Disaccharides are made up of two monosaccharides which combine. Two examples of disaccharides are lactose and sucrose. Sucrose is essentially table sugar. Sucrose can be liquid or solid. A common way to make solid sugar is granulated sugar.

Originally, sugar could only be made in liquid form as a syrup-like substance extracted from sugarcane. The process of making the sugar into granular crystals was first developed in India around 350 A.D. The word sugar, in fact, comes ultimately from the Sanskrit word sharkara meaning a substance that is composed of grains. The making of solid granular sugar gradually spread to the Mediterranean world and elsewhere. By the 16th century, sugarcane plantations were established in the Americas, expanding the reach of sugar production farther still. Modern granulated sugar was first produced in the mid-19th century and introduced in 1853 by the Boston Sugar refinery in the United States, though it was not widely sold until the late 19th century. Today, granulated sugar is made all over the world and is what most people think of when they hear the word sugar.

What is Castor Sugar?

Castor sugar, also called caster sugar, is sugar that is small enough to be dispensed through a caster, a device used for spreading salt, sugar, pepper and other granular substances onto a dish. It is similar to powdered sugar, but the grains are larger. Unlike larger forms of sugar, caster sugar can be easily dissolved and is used in making cocktails. As a result, it is often used in bars. Caster sugar is also used in other recipes where rapid dissolution of the sugar is important. The reason they dissolve easily is because the sugar crystals are particularly small making the dissolution process easier. Caster sugar can be made at home by grinding larger grains of sugar into smaller grains. In cooking, caster sugar is often used as a topping.

For most of the history of processing sugar, sugar came in the form of large sugarloaves that had to be broken down into smaller crystals to be effectively used. Because of this, there was a technological limitation to the sugar crystal size possible. It was not until the 19th century that caster sugar became widespread.

Similarities between granulated sugar and caster sugar

Caster sugar and granulated sugar are both granular and chemically composed of sucrose. They are also both very common forms of sugar. Caster sugar, in fact, can be made from granulated sugar by grinding granulated sugar crystals into crystals the size of caster sugar crystals.

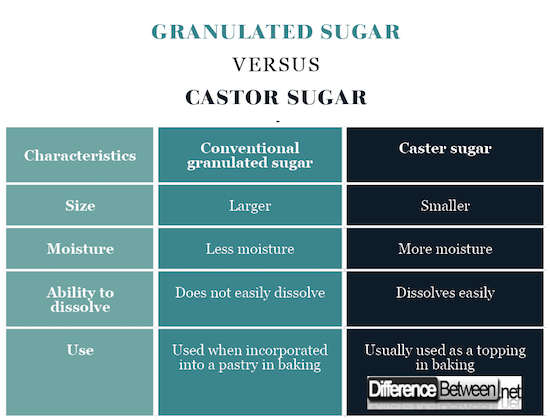

Differences between granulated sugar and castor sugar

Granulated and caster sugar are similar in many ways but also different in other ways. The differences include the following.

-

Size of Granulated sugar vs Castor sugar

Granulated sugar has a larger grain size than caster sugar.

-

Ability to dissolve

Caster sugar dissolves more easily because it is composed of smaller crystals than granulated sugar.

-

Moisture in Granulated sugar vs Castor sugar

Granulated sugar takes in less moisture due to its large grain size. This is one reason that granulated sugar does not cake or clump together easily. Caster sugar, since it is smaller, will take in more moisture and be more likely to clump or cake.

-

Use in Cooking

Granulated sugar is usually used when sugar is incorporated into the bulk of a dish such as a pastry. Caster sugar is more often used as a topping in making pastries and other baked foods.

Granulated sugar vs. castor sugar: Comparison table

Summary of Granulated Sugar vs Castor Sugar

Granulated sugar is composed of crystalline grains of sucrose which is a disaccharide containing glucose and fructose. Sucrose usually occurs in sugarcane and fruit. The large size of typical granulated sugar crystals means that they will not lump or cake as easily, but it also means that it is more difficult for the sugar to dissolve. Caster sugar is smaller than granulated sugar. The smaller crystals of caster sugar make it easier to dissolve caster sugar. Caster sugar is also more likely to cake together at high temperatures. Caster sugar is often used in making cocktails because the ease of dissolving it. Caster sugar is more often used as a topping while granulated sugar will often be incorporated into the interior of pastries. The process for making granular sugar from sugarcane was first developed in India around 350 A.D. From India it spread to Persia, China, and to the West and reached the West Indies by the 16th century. Modern granulated sugar was first produced around 1850 and came into widespread use in the late 19th century. Caster sugar also only became widely available in the 19th century when the process of breaking sugarloaves into sugar crystals of the right size became practical and affordable.

- Difference Between Environmental Performance Index and Development - November 24, 2023

- Difference Between Environmental Intervention and Development - November 8, 2023

- Difference Between Eco Efficiency and Eco Effectiveness - September 18, 2023

Search DifferenceBetween.net :

Leave a Response

References :

[0]Pennington, Neil L., and Charles W. Baker, eds. Sugar: user's guide to sucrose. Springer Science & Business Media, 1990.

[1]Adas, Michael, ed. Agricultural and pastoral societies in ancient and classical history. Vol. 79. Temple University Press, 2001.

[2]Helmenstine, Anne Marie, Ph.D. "What Is the Chemical Formula of Sugar?" ThoughtCo, May. 9, 2017, thoughtco.com/chemical-formula-of-sugar-604003.

[3]Mescher, Virginia. “HOW SWEET IT IS!” A HISTORY OF SUGAR and SUGAR REFINING IN THE UNITED STATES INCLUDING A GLOSSARY OF SWEETENERS. Accessed 13/04/16) Published online http://www. raggedsoldier. com/sugar_history. pdf, 2005.

[4]Image credit: https://pixabay.com/en/sugar-granulated-sugar-sugar-cube-2510536/

[5]Image credit: https://upload.wikimedia.org/wikipedia/commons/thumb/a/a4/White_cane_sugar.JPG/640px-White_cane_sugar.JPG