Difference Between Soldering and Brazing

Soldering and brazing jointly represent one of several methods used for joining two or more pieces of metal. In essence, a joint is made in metal using an alloy of two or more metals to hot-glue the parts together. The word “glue” here does not mean just sticking something together as the items to be joined are to be bonded at a molecular level to the alloy, which imparts considerable strength to the joint. Soldering and brazing are the only metal joining methods that can produce smooth and rounded fillets at the periphery of the joints. Both the operations involve heating the filler metal and joint surfaces above ambient temperature. Both are essentially the same metal joining technique, the difference being the temperature at which each method is performed. Brazing filler metals melt above 450 °C where as solder filler metals melt below 450 °C. Let’s take a look.

What is Soldering?

Soldering is one of the oldest and most popular techniques used for joining similar or dissimilar metals. It uses a filler material to join parent materials that remain solid. It is a low-temperature analog to brazing which uses filler alloys with melting temperatures below 450 °C (840 °F). This process may or may not require a fluxing agent. The filler metals melt at low temperatures so there is minimum part distortion and heat damage to sensitive parts. The filler metal is called solder which when solidifies, is then bonded to the metal parts to join them. The most commonly used solder is tin alloy and lead. Soldering is extensively used in the electronics industry for joining wires, capacitor, resistor, etc. with the joining plate.

What is Brazing?

Brazing is yet another metal joining process in which two or metals are joined together by heating and melting a filler metal, which then bind the two pieces together and join them. It can be applied to a wide variety of materials, including metals, ceramics, glasses, plastic, and composite materials. Although it is not as strong as fusion welding, it is the strongest form of metal bonding without melting the parent metal of the components being joined together. So this process requires more heat input than other soldering operations such as mechanical fastening, adhesive bonding, solid state joining, welding and so on. This process can also be used to join dissimilar metals such as silver, gold, copper, aluminum, etc. Brazing is necessarily done at temperature above 450 °C but below the critical temperature of metal.

Difference between Soldering and Brazing

-

Terminology of Soldering and Brazing

– Both soldering and brazing are metal joining processes used to join two similar or dissimilar metals but in different joining conditions. Brazing is a welding technique used to join two pieces of metal together using a metallic filler that has been melted and flowed into the joint. Soldering is one of the oldest methods of joining metals that allows electronic components to be electrically joined such as wires, capacitors, resistors, etc. It also uses a filler metal called solder to fill the joint which makes an alloy at the metal surface but the base metal is not melted.

-

Temperature

– Soldering and brazing refer to a group of metal joining processes in which two or more similar or dissimilar metals are coupled together by melting and filling a filler metal into the joint. Brazing is carried out at temperatures approaching the fusion temperatures used in welding. Both are essentially same techniques used to join metals, the key difference being the temperature at which each process is carried out. It is mainly done at temperature above 450 °C but below the critical temperature of metal. The soldering process, on the other hand, uses filler alloys with melting temperatures below 450 °C (840 °F)

-

Applications

– Soldering is the process mostly used in electronic industry to form a permanent connection between the electronic components. It is commonly used in plumbing works, electronics, arts and crafts, engine repairs, and metal works from flashing to jewelry. It is mostly used to join wires to leads of components such as switches. In brazing flux is used to promote wetting and to remove oxides from the base material so that the filler metal bonds well with the metal parts. It is mainly used to join all kinds of metals except aluminum and magnesium. It is also used in automotive industries.

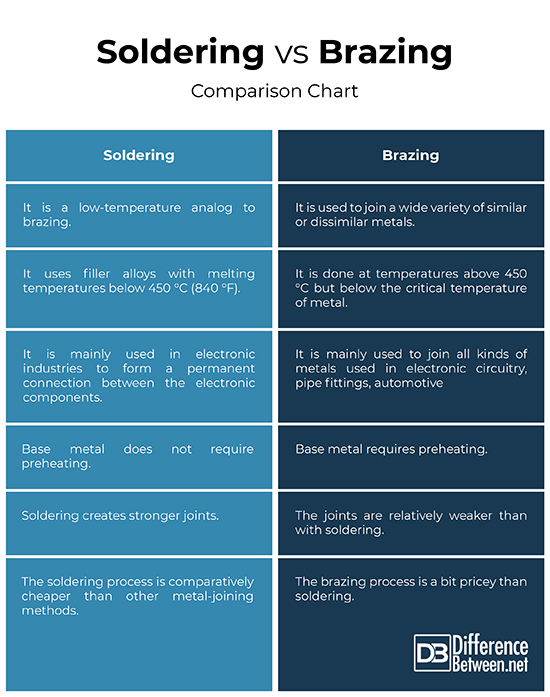

Soldering vs. Brazing: Comparison Chart

Summary of Soldering Vs. Brazing

Both soldering and brazing are the two most common methods used for joining two or more pieces of similar or dissimilar metals in which a filler metal is melted and filled into the joints. Both the processes are quite the same, except soldering uses filler alloys with melting temperatures below 450 °C (840 °F) whereas brazing is to be carried out at temperatures above 450 °C. Soldering is commonly used in plumbing works, electronics, arts and crafts, engine repairs, and metal works from flashing to jewelry. Brazing is mainly used to join all kinds of metals in mechanical industries such as automotive industry. Brazing requires more heat input than any of the other soldering operations thus uses a more general heat source in the form of a gas blowlamp.

- Difference Between Caucus and Primary - June 18, 2024

- Difference Between PPO and POS - May 30, 2024

- Difference Between RFID and NFC - May 28, 2024

Search DifferenceBetween.net :

4 Comments

Leave a Response

References :

[0]Image credit: https://upload.wikimedia.org/wikipedia/commons/thumb/f/f8/Soldering_a_0805.jpg/640px-Soldering_a_0805.jpg

[1]Image credit: https://upload.wikimedia.org/wikipedia/commons/thumb/8/81/Cyfac_filet_brazing_custom_steel_bicycle..JPG/640px-Cyfac_filet_brazing_custom_steel_bicycle..JPG

[2]Lofting, Richard. Brazing and Soldering. Marlborough, UK: The Crowood Press, 2014. Print

[3]Schwartz, Mel M. Soldering: Understanding the Basics. Ohio: ASM International, 2014. Print

[4]Jacobson, David M., and Giles Humpston. Principles of Brazing. Ohio: ASM International, 2014. Print

I gotta good ideas and well explained notices

Thanks for the answer

But I asked for the similarities of soldering and brazing

Brazing is not weaker as your chart shows. WRONG